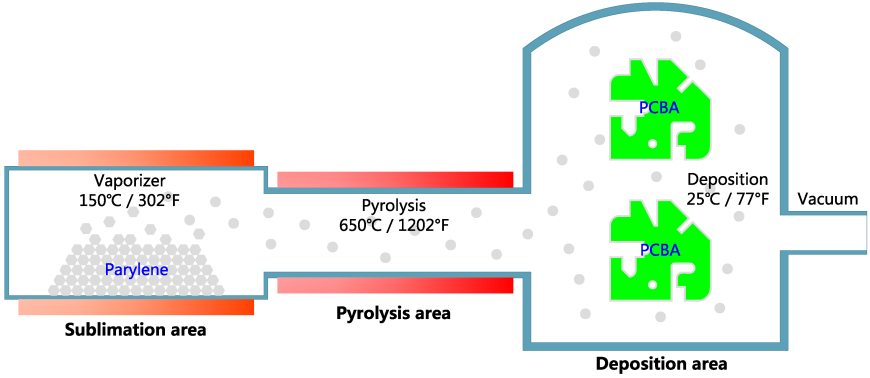

CVD(Chemical Vapor Deposition),also knows as parylene coating or nano coating.CVD is a technology that is a deposition method used to produce high quality,high-performance,solid materials.The process is often used in the semiconductor industry to produce thin films(0.1-100um).In typical CVD,the part is exposed to one or more volatile precursors,which react and/or decompose on the part surface to produce the desired deposit.Frequently,volatile by-products are also produced,which are removed by gas flow through the reaction chamber.The coating is uniform in thickness, compact without pinhole,transparent without stress and without auxiliary agent, and has excellent electrical insulation and protection. It is the most effective anti-moisture,anti-mildew, anti-corrosion and anti-salt fog coating material.

CVD Process

After the coating, the electronics will have high-dielectric strength and excellent resistance to high and low temperature(-100-200 degree C), anti-corrosion, acid and alkali resistant, lubricating, resistant to dust, moisture and rust. It is a transparent and water proof (IP68), anti-aging, biocompatible material.

LPMS designed CVD equipment and used it in the electronics industry. We provide turnkey solution from material,technology and equipment. CVD is wildly used in aviation, PCBA, LED, magnetic material, sensors, silicon rubber, sealing element, medical equipment, precious cultural relics and etc.

Copyright ? 2015-2018 LPMS International Ltd. All Rights Reserved.